Our health is deeply interconnected with the health of our planet. Caring for Earth's health is non-negotiable.

Each Stack capsule sold removes twice its plastic weight from the environment.

Our health is deeply interconnected with the health of the Earth. For every gram of medical-grade plastic in Stack, we fund the removal of two grams of ocean-bound plastic, verified by independent partners. We hope other companies that require the use of plastic in their packaging will join us in our 2:1 Reclamation commitment.

12,000 pounds

of ocean-bound plastic removed so far

Net Environmental Impact

Scenario

Plastic Introduced

Plastic Reclaimed

Net Change

Consumer Doesn't Recycle

Consumer Does Recycle

Our Packaging is 100% Recyclable

We follow Dieter Rams’ rule that good design is environmentally friendly. Every material in our packaging was chosen to recycle easily while still having a purpose.

Cardboard Box

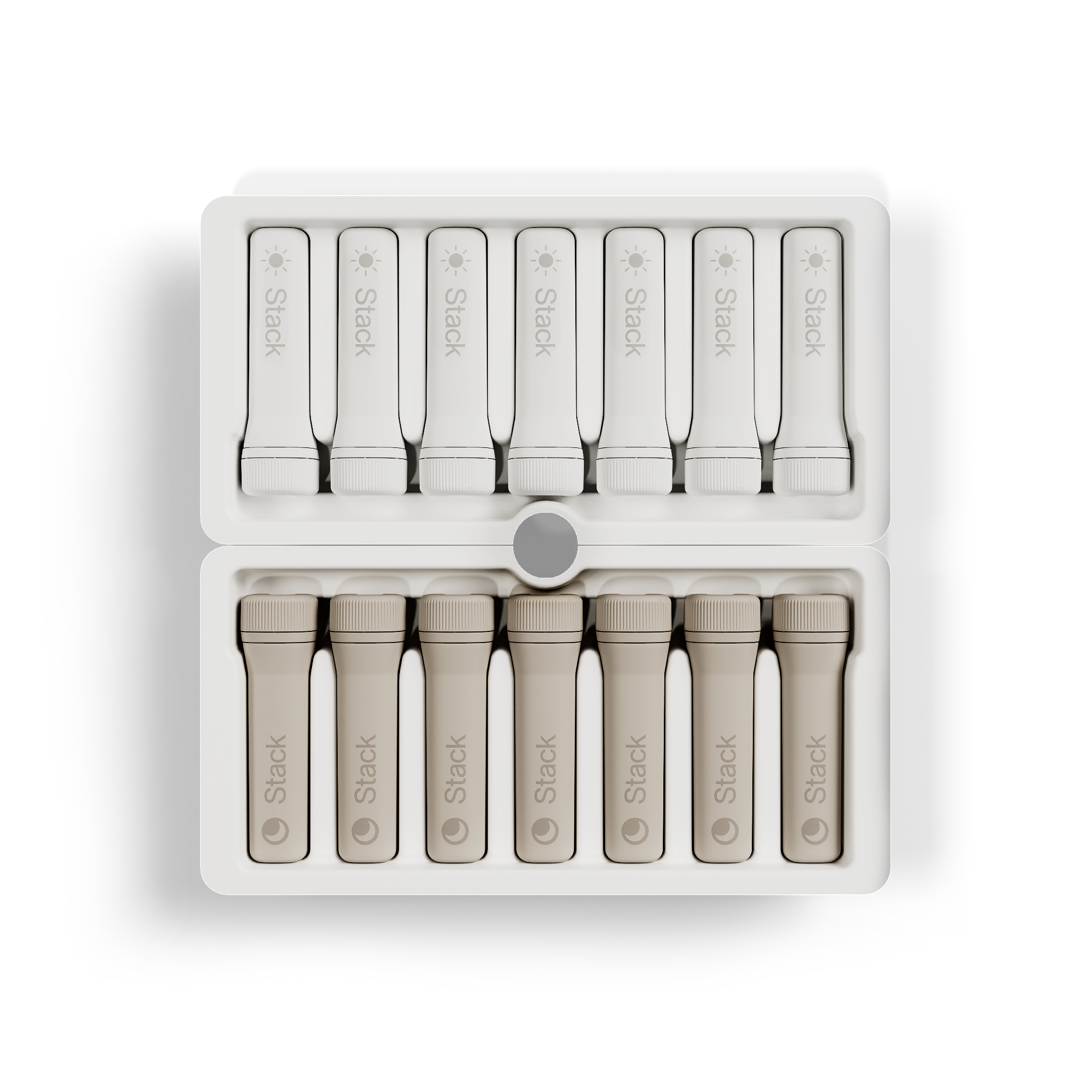

Paper Pulp Trays

Capsules

Why does Stack use medical-grade plastic instead of glass or aluminum?

After consulting with expert material scientists, we weighed the five factors below to make our decision. Aluminum needs a plastic liner that can shed microplastics, glass can splinter into fine shards, but polypropylene stays stable and fully recyclable. Our 2:1 Reclamation pledge then makes polypropylene net-negative for plastic in the environment.

Net Environmental Impact

Test

Aluminum

Glass

Medical-grade Polypropylene

Energy to Shape

Breakage in Transit

Extra Coatings Needed

Microplastic Risk

Net Plastic After 2:1

Reclamation Commitment

Summary

Our health is tied to the health of our planet.

Phi exists to lengthen human healthspan, so caring for Earth’s health is non-negotiable.

We are committed to our 2:1 Reclaimed pledge.

Each gram of plastic in Stack removes two grams of ocean-bound plastic, verified by independent audits.

Every component of Stack is 100% recyclable.

Box, trays, and capsules all drop into everyday bins, no special sorting required.

Frequently Asked Questions

We Want Your Help

We have collaborated with material scientists and recycling experts to ensure our choices strike the right balance between product safety and sustainability. We would be thrilled to hear your insights on how we can further improve.